At VCS Floorworks, Solid Timber and Engineered floors are what we focus on. We have a long history in supplying timber and all the related products.

Engineered floors are a type of flooring that consists of multiple layers of different materials that are designed to provide structural stability and resistance to humidity and temperature changes. Timber is a dynamic material that expands and contracts as it is affected by humidity swings. Engineered floors are considerably more stable floors than solid timber floors.

Why 14mm is usual

Engineered floors are traditionally manufactured in 14mm thickness for several reasons, one of which is their suitability for transitions to other floor levels in homes.

The 14mm thickness of engineered floors is considered ideal for transitions to other floor levels in homes for the following reasons:

- Height compatibility: A 14mm thick engineered floor provides a good balance between thickness and height, making it easier to create smooth transitions to other types of flooring or floor levels within a home. This thickness allows for almost seamless transitions between rooms with different types of flooring, such as tiles and carpet, without the need for extensive adjustments or transitions strips.

- Stability and durability: A 14mm thick engineered floor typically provides sufficient structural stability and durability to withstand regular foot traffic and other loads. This thickness helps ensure that the floor remains stable and level over time, even when transitioning between different floor levels.

- Installation flexibility: The 14mm thickness of engineered floors offers flexibility in installation options, allowing for both floating installation methods and direct glue-down installations. This versatility makes it easier to adapt the flooring to different areas of the home and accommodate transitions to varying floor levels. We recommend fitting floors permanently using adhesive to greatly extend the life of the flooring.

- Aesthetic appeal: The 14mm thickness of engineered floors can contribute to a visually appealing transition between different floor levels, creating a cohesive and seamless look throughout the home. The thickness of the flooring can help create a smooth and harmonious flow between spaces, enhancing the overall aesthetic of the interior design.

Overall, the 14mm thickness of engineered floors is considered ideal for transitions to other floor levels in homes due to its height compatibility, stability, durability, installation flexibility, and aesthetic appeal, making it a practical and versatile choice for residential flooring applications.

The Important Core

One of the key components of engineered floors is the core layer, which is typically made of plywood.

Plywood is a popular material for the core of engineered floors for several reasons:

- Stability: Plywood is made by gluing together multiple layers of wood veneer with each layer positioned at right angles to the adjacent layers. This cross-grain construction gives plywood excellent dimensional stability, meaning it is less prone to expansion and contraction due to changes in humidity and temperature compared to solid wood.

- Strength: Plywood is a strong and durable material that can withstand heavy loads and resist impacts better than solid wood. This strength is important for ensuring the structural integrity of the engineered floor.

- Resistance to warping and twisting: The layered construction of plywood helps to distribute stress evenly across the material, reducing the likelihood of warping or twisting over time. This is particularly important for flooring applications where maintaining a flat and level surface is crucial.

- Cost-effectiveness: Plywood is generally more affordable than solid hardwood, making it a cost-effective option for the core layer of engineered floors. This can help make engineered flooring more accessible to a wider range of customers.

Plywood is a good choice for the core of engineered floors due to its stability, strength, resistance to warping, and cost-effectiveness, making it a reliable and practical material for this application.

Choices

In engineered flooring, a variety of timber species from Australia and Europe are commonly used to provide different aesthetics, durability, and characteristics. Here are some of the major Australian and European timbers that are popular choices for engineered flooring:

Australian Timbers:

- Jarrah: Jarrah is a native Australian hardwood known for its rich red-brown color and durability. It is commonly used in engineered flooring for its unique grain patterns and resistance to wear and tear.

- Spotted Gum: Spotted Gum is another popular Australian hardwood with a range of colors from light cream to dark brown. It is valued for its durability, strength, and attractive grain patterns, making it a great choice for engineered flooring.

- Blackbutt: Blackbutt is a lighter-colored Australian hardwood with a straight grain and even texture. It is prized for its versatility, durability, and natural beauty, making it a popular option for engineered flooring.

- Sydney Blue Gum: Sydney Blue Gum is a hardwood species native to southeastern Australia. It features a distinctive pink to red-brown color with a straight grain and an even texture. It is often used in engineered flooring for its attractive appearance and durability.

European Timbers:

- Oak: European Oak is one of the most commonly used timbers in engineered flooring worldwide. It is prized for its durability, stability, and distinctive grain patterns. European Oak can be found in various finishes, including natural, stained, and distressed, offering a wide range of design options.

- Ash: European Ash is a light-colored hardwood with a prominent grain pattern. It is valued for its strength, flexibility, and overall durability, making it an excellent choice for engineered flooring in both residential and commercial settings.

- Maple: European Maple is a light-colored hardwood with a smooth, fine texture. It is valued for its hardness, stability, and uniform appearance, making it a popular choice for contemporary engineered flooring designs.

These are just a few examples of the major Australian and European timbers commonly used in engineered flooring. Each timber species offers unique characteristics and aesthetics, allowing homeowners and designers to choose the flooring that best suits their preferences and design requirements.

Other Choices

Another option is pre coloured Oak flooring in engineered boards. Supplying oak floors as engineered boards with a stained finish offers several benefits that can enhance interior design aesthetics and functionality. Here are some reasons why this option is advantageous and how it can help in interior design:

- Enhanced Durability: Engineered oak boards are more dimensionally stable than solid oak boards, making them less prone to warping, cupping, or shrinking due to changes in humidity and temperature. This increased stability ensures that the flooring maintains its appearance and structural integrity over time, reducing the need for repairs or replacements. Stained finishes can be repaired when a single colour stain is used and this is another benefit.

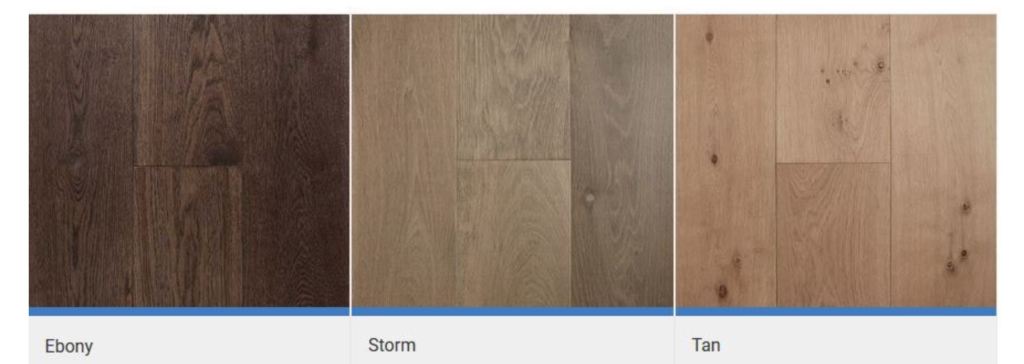

- Wide Range of Stain Options: Staining oak floors allows for a wide range of color options to choose from, enabling homeowners and designers to achieve the desired look and style for their space. Whether it’s a light, natural finish to brighten the room or a dark, rich finish to add warmth and depth, stained oak floors offer versatility in design choices.

- Customization: Staining oak floors provides a way to customize the flooring to complement the overall interior design scheme of a space. By selecting the right stain color and finish, homeowners can coordinate the flooring with existing furniture, decor, and color palettes to create a cohesive and harmonious design aesthetic.

- Visual Appeal: Stained oak floors can add depth, character, and visual interest to a room. The natural grain patterns and texture of oak wood can be enhanced by the stain, creating a beautiful and unique look that adds warmth and sophistication to the space. Different stain colors can also help create contrast or blend seamlessly with other design elements in the room.

- Versatility: Stained oak floors are versatile and can complement a variety of interior design styles, from traditional to modern. Whether used in a rustic farmhouse setting, a contemporary urban loft, or a classic formal space, stained oak floors can adapt to different design themes and aesthetics, adding a timeless and elegant touch to any room.

Overall, supplying oak floors as engineered boards with a stained finish offers durability, customization options, visual appeal, versatility, and the ability to enhance the overall interior design of a space. It provides homeowners and designers with a versatile flooring solution that can elevate the style and ambiance of any room.

The Range Continues To Grow

The range of engineered floors continues to grow, offering consumers a wide variety of sizes and styles to choose from. Here are some ways in which sizes and varieties of engineered floors are changing:

- Plank Width and Length: Engineered floors are now available in a broader range of plank widths and lengths to cater to different design preferences. In addition to traditional narrow planks, wider planks are becoming increasingly popular for a more contemporary and spacious look. Longer planks can also create a sense of continuity and expansiveness in a room.

- Thickness Options: While 14mm thickness is still common for engineered floors, manufacturers are offering a range of thickness options to meet various installation needs and requirements. Thicker engineered floors may be preferred for areas with heavy foot traffic or where sound insulation is a concern.

- Surface Finishes: Engineered floors come in a variety of surface finishes, including matte, satin, semi-gloss, and high-gloss finishes. Each finish offers a different look and feel, allowing homeowners to choose the one that best suits their design preferences and lifestyle.

- Textured Finishes: Textured finishes such as hand-scraped, wire-brushed, distressed, or saw-marked surfaces are gaining popularity for adding depth, character, and a rustic charm to engineered floors. These textures can help conceal minor wear and tear, making them ideal for high-traffic areas.

- Color and Stain Options: Manufacturers are offering a wider range of color options and stains for engineered floors, allowing homeowners to choose from various shades and tones to match their interior design scheme. From light, natural finishes to dark, rich hues, there are plenty of options to suit different styles and preferences.

- Mixed Media and Patterns: Some engineered floors are now incorporating mixed media elements such as metal accents, inlays, or patterns to create unique and customized designs. Chevron, herringbone, and other intricate patterns are also becoming more popular for adding a touch of elegance and sophistication to a space.

- Environmentally Friendly Options: With increasing focus on sustainability, eco-friendly engineered floors made from renewable or recycled materials are gaining popularity. These options offer environmentally conscious consumers a way to reduce their carbon footprint while still enjoying the beauty and functionality of engineered flooring.

Overall, the range of sizes and varieties of engineered floors is expanding to meet the evolving needs and preferences of consumers. With a wide selection of sizes, styles, finishes, colors, textures, and eco-friendly options available, homeowners have more choices than ever to create a personalized and stylish look for their living spaces.